While some trailer accessories are needed as a maintenance product, others are purely for aesthetic appearances. In either case, you will want something that lasts and maintains the function for what it was intended. You count on your boat trailer, so be sure you give it the right tools for the job.

Here are some of the boat trailer accessories we will be looking at in this article today. They range anywhere from a “need” to a “want”, but they are all great trailer accessories that you should check out.

- Greaseable bearing hubs (Bearing Buddy)

- Winch

- Tie down straps

- Lighting

- Bunks, guides, and rollers

- Couplers

- Locks

- Wheels and tires

- Fenders

- Bow support posts and more

This is a sample of the type of boat trailer accessories that we’ll cover today. Having had dozens of trailers over the years, I have had to work on just about every part a trailer has. I have torn trailers down to just a frame with no suspension or any other components in order to refurbish into a new trailer with all new components. So let’s take a look at some of the great boat trailer accessories I’ve found.

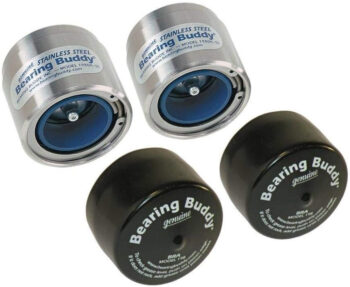

Bearing Buddy Greaseable Bearing Hubs

Bearing Buddy bearing protectors are one of the very best trailer accessories you can buy, and they cost so little! They function as an easy way to add grease to your trailer wheel bearings without having to disassemble them. So if your trailer doesn’t already have these, then absolutely get them now. They install easy and feed your bearings the grease they need.

Bearing Buddy bearing protectors are one of the very best trailer accessories you can buy, and they cost so little! They function as an easy way to add grease to your trailer wheel bearings without having to disassemble them. So if your trailer doesn’t already have these, then absolutely get them now. They install easy and feed your bearings the grease they need.

Once your new Bearing Buddy set arrives, this is the best time to get your bearings cleaned, packed, and adjusted prior to installation. (If you recently did this, then skip to step 12. However, if you haven’t cleaned and adjusted them, you need to do all theses steps this time). A Bearing Buddy is designed to make it simple to put a couple pumps of grease into your hubs so there is fresh grease on the bearings all the time. This really extends the time between adjustments or replacements. Here is what you’ll do:

- Put your trailer up on jack stands and remove all the wheels.

- Remove the bearing dust caps. You won’t need these anymore.

- Remove (work on one side at a time from here) the cotter pin and then remove the nut, and place dirty parts in a plastic container.

- Pull the wheel hub off while being sure to not drop the outer bearing. (Keep track of the order the bearings and washers come off). Then put the bearing in the plastic container.

- Take the inner bearing off the spindle and put it in the plastic container.

- Now clean the grease and dirt from all the parts using a parts washer solvent and a parts cleaning brush. (Links go right to Amazon for the best price)

- Don’t forget to also clean your wheel hub, and then, using compressed air and a clean rag, dry out parts completely.

Repack your bearings with marine grade grease. I pack by putting grease in my palm and working the grease into the bearing, which is time consuming. There is a bearing packer kit on Amazon that some people use to speed up the process. I haven’t tried it though.

Repack your bearings with marine grade grease. I pack by putting grease in my palm and working the grease into the bearing, which is time consuming. There is a bearing packer kit on Amazon that some people use to speed up the process. I haven’t tried it though.- Now with both bearings packed with grease, reinstall the parts and tighten nut to slightly snug, then back the nut off.

- With your fingers tighten the nut to where it gets slightly snug and then back off again to the first notch in the nut that the cotter pin will reinsert.

- Bend the cotter pin tabs around the nut.

- Grab your bearing buddy and a small block of wood and fit the bearing buddy into your wheel hub (with the zerk fitting facing out), and using a hammer, hit the block of wood to evenly drive the bearing buddy into the wheel hub until it is fully set.

- Using your grease gun (this is an excellent one with great accessories from Amazon) with the marine grade grease, pump grease into the bearing buddy as the directions state.

- Clean up any grease off your wheel hub and repeat the steps for the other wheel (or wheels).

From this point you only need to worry about adding grease after having driven a lot of miles. You also will want to check your bearing adjustments once in a while. Just jack up your trailer and spin the wheel making certain that it rotates several turns freely. Also, grab two sides of the tire and try to rock it, in and out and side to side. There should be very slight movement in the bearing. If you have them adjusted too tight, the bearings will wear out prematurely. You will find that with greasing the Bearing Buddy a few times per season (more if you travel far with the trailer), your bearings will not need adjustments for a very long time.

Trailer Winch

Choosing the correct boat trailer winch for your situation is important, because you don’t want to break your winch at the loading dock. This is going to leave you in a bad situation. So going cheap and buying a low rating winch, just may make you wish you followed this article. There are a few factors that you need to consider when sizing up your winch choice.

- The weight of your boat and all of it’s contents.

- The steepness of the boat ramp.

- Does your boat trailer have rollers or bunks.

- Are you backing the trailer far enough into the water.

There are varying results across boater’s opinions on the capacity requirements for a boat trailer winch. That’s because of the factors above are different for many boaters. What I have found, is that the major factor causing the difference in opinion, is that many boaters ask more of their winch than is needed. The simple fact is that if the boat trailer is backed into the water correctly, it just doesn’t take that much power to pull your boat up to the bow roller. Read this article on properly loading your boat, and then come back to this article to pick the correct winch for your situation.

Personally, I think you can figure your winch choice simply by selecting a winch that is a minimum of 1/2 the capacity of your boat and contents weight. So for example, a boat and it’s contents that weighs 6,000 pounds, should have a boat trailer winch with a capacity of at least 3,000 pounds. With that said (and I’ll explain more in a minute), why go with the minimum rating? With the pricing of boat trailer winches being so reasonable and not much of an increase to step up to the next higher rating, why not be sure about your winch?

Your winch has a couple jobs that it needs to accomplish. It needs to pull your boat up onto the trailer (hopefully you read the article above). It also needs to hold your boat on the trailer during transportation. Your trailer must be equipped with a bow safety chain and you should always hook it up, but that is only for in case of your winch failure while your boat is on the trailer. Your winch strap runs under your bow roller and up to the bow eye/cleat on your boat. This allows for pulling forward pressure and downward pressure on your boat. This holds your boat down and forward on the trailer. Your transom straps do the same for the back of your boat.

So in the case above, where you have a 6,000 pound boat sitting on your trailer, there would have to be a force of 9,000 pounds in order to lift up your entire boat and then meet the 3,000 pound force against the winch. Clearly this isn’t likely to happen, because you have your transom straps on and the trailer isn’t held down to the ground in order to create this force anyway. Now from the standpoint of pulling your 6,000 pound boat up to the bow roller on the trailer, you are not dragging the entire weight of the boat. With the trailer properly backed into the water, your boat is mostly still floating in the water.

Who in their right mind is backing their trailer up to the water’s edge and cranking the boat up the bunks the entire length of the trailer. Well, NOBODY, lol. So there is the factor of the steepness of the boat ramp that may add an extra drag/friction factor to winching up your boat. Again though, take note of how far in the water the trailer is backed in. You want the boat to hit the bunks and center itself and then winch the boat up a couple feet to the bow roller. This way as you pull the trailer out of the water slowly, the boat has a chance to center and settle onto the trailer. If your trailer has rollers, it’s even easier.

You can get a manual winch that you crank up by hand or for larger boats you may chose to have an electric winch. You could go to your local marine store or other websites to find a boat trailer winch, but the reality is you will pay more for the same quality that you will get on Amazon. The other thing is, the ease and selection just can’t be beat. Also it just shows up to your door without you running out at all and if you don’t like it, it’s easy to return. Some specific boat parts do need to be OEM specific to your boat, but when it comes to accessories, gear, safety, towables, etc. you just can not beat Amazon. Lets look at a couple great boat trailer winch options.

Here is a manual hand crank boat trailer winch. This is available in a 1,600 pound rating as well as a 3,500 pound rating. This is a durable, well built winch. It has a two way ratcheting feature, so you can safely ratchet in or out. The 3,500 pound version also has two speeds if you want to crank it in quicker. These will mount onto your existing winch platforms and it does come with the mounting hardware so you don’t need to reuse the old stuff.

Here is a manual hand crank boat trailer winch. This is available in a 1,600 pound rating as well as a 3,500 pound rating. This is a durable, well built winch. It has a two way ratcheting feature, so you can safely ratchet in or out. The 3,500 pound version also has two speeds if you want to crank it in quicker. These will mount onto your existing winch platforms and it does come with the mounting hardware so you don’t need to reuse the old stuff.

The 1,600 pound rating winch will be good for smaller watercrafts and usually up to a 20 foot long fiberglass fishing boat. The larger 3,500 pound rating winch will handle most boats up to 25 or 26 foot that are of fiberglass construction. From there you will certainly want to step up to a higher capacity boat trailer winch, and most likely you’ll want electric powered.

This takes us into the rage of wanting an electric powered boat trailer winch. My pick for this is great as it is available in 3 different weight ratings. This one is also available in a 3,500 pound rating, but you can get it in a 6,000 pound rating and a 13,500 pound rating!

This takes us into the rage of wanting an electric powered boat trailer winch. My pick for this is great as it is available in 3 different weight ratings. This one is also available in a 3,500 pound rating, but you can get it in a 6,000 pound rating and a 13,500 pound rating!

Each weight rated version comes with synthetic rope, which is perfect for this. Synthetic rope is incredibly strong and doesn’t rust, so it always looks nice. All versions also come with a wired controller as well as wireless controllers. You can wire your tow vehicle for a power source, or mount a battery on the trailer tongue (Be sure to mount it in a location that will not be submerged in the water). You could carry a separate battery. The last two choices allows for any vehicle to tow your boat to the lake and still have a power source for your winch.

Boat Tie Down Straps

A boat needs to secured to it’s trailer during transport with tie down straps. It’s the law, but if you you don’t tie it down, a big bump in the road or an accident can throw your boat of your trailer and ruin your boat. The boat could also hit other things when it falls off, that may ruin someone’s life. Let me show you a couple options.

As I mentioned above, your winch is holding down the bow of your boat to the trailer. Your bow safety chain is hooked up in case there is a failure at the winch. Some people get lazy and skip hooking this up, which is illegal and unsafe. If you don’t have one on your trailer, you should get one and use it. A couple years back, I saw a guy at the boat ramp winch his boat up onto his roller trailer. Then he jumped in his truck and pulled forward, and at the top of the ramp, his winch strap broke. His boat rolled off his trailer and onto the boat ramp. The safety chain was just hanging there, because he didn’t think he needed it.

If he had to learn his lesson, this was the best place for it to happen. There are generally four tie downs that hold a boat to the trailer.

- The winch holding the bow of the boat in place

- The bow safety chain acting as a backup to the winch

- The port side transom tie down strap

- The starboard side transom tie down strap

There generally aren’t safety backup chains to the transom straps. It’s assumed that the bow being held by a safety chain is sufficient. So since we covered the winch and bow safety chain, lets look at a couple options for holding the back of the boat in place with transom straps.

Amazon has the G2 retractable transom tie down straps that are my first choice for most of the boats I have had and worked on. For me the biggest reason is that they are great quality and they fully retract out of the way. Just bolt them onto the trailer and pull the strap out to hook to the transom eyelet, then ratchet it tight. There is a button that will release the strap so you can retract them out of the way for launching your boat.

Amazon has the G2 retractable transom tie down straps that are my first choice for most of the boats I have had and worked on. For me the biggest reason is that they are great quality and they fully retract out of the way. Just bolt them onto the trailer and pull the strap out to hook to the transom eyelet, then ratchet it tight. There is a button that will release the strap so you can retract them out of the way for launching your boat.

The one’s I buy have a 2,500 pound breaking strength each. You would have to hit a bump or have an accident that would cause a lift of the entire weight of the boat, plus and additional 5,000 pounds of lift, all while holding the trailer to the ground, in order to break these straps! I can’t really think of a scenario that can do this, but be sure you choose the strength of transom straps you personally feel you need.

With the G2 retractable transom tie down straps, you don’t have to worry about remembering where you put them, because they are always right there waiting for you to use. However, if you want a lower price option, they will be two individual straps that you have to fully remove off the boat and trailer and then store them somewhere. Let’s check out a good set for you next.

For an unmounted version of transom tie down straps, these are quite strong with a break strength of 3,300 pounds each. Made in New Zealand, these quality made ratcheting straps will not stretch when wet. The hooks are coated in PVC so they won’t scratch your boat. Since these are fully removable straps, the hooks have safety clips on them, so if one was to ever become loose because of boat shifting on the trailer, the strap would not fall off the boat or trailer.

For an unmounted version of transom tie down straps, these are quite strong with a break strength of 3,300 pounds each. Made in New Zealand, these quality made ratcheting straps will not stretch when wet. The hooks are coated in PVC so they won’t scratch your boat. Since these are fully removable straps, the hooks have safety clips on them, so if one was to ever become loose because of boat shifting on the trailer, the strap would not fall off the boat or trailer.

With a combined 6,600 breaking strength, you’ll have these forever, but keep in mind that you will have to tie up the excess strap once you ratcheted them down each time. You will also have to make a habit of putting them in the same place each time you take them off, so you don’t misplace them. I would suggest having a backup system in case you loose them, but they are great transom tie down straps at approximately half the cost of the G2’s, but for the convenience, I do like the G2 system better.

Boat Trailer Lighting

There are a few different kinds of lighting for boat trailers. But let’s start off talking about the normal safety lighting for boat trailers that have to be submersible. With the advent of LED lighting, trailer lights have gotten much brighter and more reliable. Back in the old days, lol, the light bulbs would be popping all the time. Whether it was water getting in the lens, or just the constant beating the filaments took going down the road.

Now we have these fantastic submersible trailer light kits that are pretty much trouble free and last many years. The kit to the right is from Partsam and is incredibly low priced on Amazon for everything you get with it. It is truly complete to light your entire trailer. Your trailer will be lighted all the way around. If I had one thing to say about wiring kits these days, it would be that the splicers that come in the kits work fine. However, I am a proponent of soldering my wire connections and putting shrink ban on them.

Now we have these fantastic submersible trailer light kits that are pretty much trouble free and last many years. The kit to the right is from Partsam and is incredibly low priced on Amazon for everything you get with it. It is truly complete to light your entire trailer. Your trailer will be lighted all the way around. If I had one thing to say about wiring kits these days, it would be that the splicers that come in the kits work fine. However, I am a proponent of soldering my wire connections and putting shrink ban on them.

I know it is easy to use these splicers, and they are in the kit because not many people know how to solder wires properly. Solder just make a much more solid and permanent connection. If you have never soldered before and want a soldered connection, there is a newer innovation that you slide your wires in each end of this connector and heat it with a heat gun to melt the built-in solder and at the same time the shrink ban is sealing it to make it waterproof. Click this link to check it out on Amazon to see if it is something you want to try.

The next boat trailer lighting kit is used as a backup set or an emergency trailer light set. Not everyone will need something like this, but I have used mine many times. If you have read many of my pages on this website, you’ll know that I have restored a lot of boats back to life. Many of those boats are not in good condition at all when I get them and neither are the trailers.

When I’m going to look at one of these dilapidated boats, I always ask what size the tires are. I never ask if the trailer lights work, because they almost never do. The tires will be weather checked and probably unsafe for travel, so I bring a good set. But more importantly, I always bring my set of magnetic emergency trailer lights. Sometimes the trailer might be aluminum (not magnetic), but I just zip-strip them onto the trailer and plug them into my truck. Actually, I use zip strips to attach them all the time because you never know if you are going to hit a big bump and one may pop off.

There are also magnetic trailer lights that are wireless. They are rechargeable and they work off a dongle (sending unit) that you plug into the vehicle’s trailer wiring socket. This unit sends a signal to the wireless lights and tells each one what to do. Of course you can view them on Amazon, but I am not going to link to any particular one, because I have not used them at all. I am totally good with using my wired set. They are awesome!

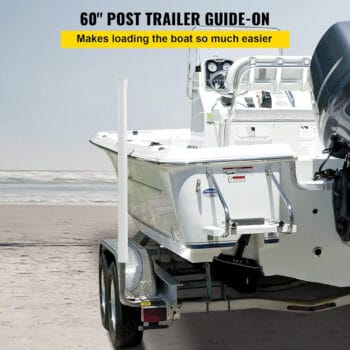

These next boat trailer lights we are going to discuss are both for safety and for a very cool effect. If you have, or want to have guide posts on your boat trailer, then these guide post lights are a must have for sure. They make the guide posts so much more effective. Boat trailer lights are usually very close to the ground and if someone is following too close, they may not see your trailer lights. Should someone be following this close? HECK NO! But some do it anyway.

These boat trailer guide post lights by Partsam are on Amazon and they are fantastic. From a safety factor, it brings another set of tail lights up higher and in plain sight. They install very easy and do everything your trailer lights do. But wait, there’s more, lol. The very top also illuminates and makes it SO much easier to see your trailer at night. Ever wonder if your trailer lights are on? Well, just look in the mirror and you can easily tell.

These boat trailer guide post lights by Partsam are on Amazon and they are fantastic. From a safety factor, it brings another set of tail lights up higher and in plain sight. They install very easy and do everything your trailer lights do. But wait, there’s more, lol. The very top also illuminates and makes it SO much easier to see your trailer at night. Ever wonder if your trailer lights are on? Well, just look in the mirror and you can easily tell.

This also aids in backing up your trailer at night. Speaking of night time. These guide post lights stick up out of the water making it easier to know exactly where to position your boat when loading after dark. You just can’t beat the usefulness of these. If you don’t have a set of guide posts to put these on, check out this set on Amazon.

Lastly, we need to look at the “cool” factor. We can make the trailer look like a landing strip for your boat, by adding some LED lights to the inside frame rails.

I’ve seen some people try this with cheap LED strips, just to have them fail or the adhesive lets go. While in most every case, great products can be sourced from Amazon with enough research. However, this is one of the rare times it doesn’t work out. This is why I am recommending you go with the top quality Bluewater LED boat trailer lighting kit. This kit is IP68 rated waterproof, which is not only submersible, but can be left underwater for the long term.

I’ve seen some people try this with cheap LED strips, just to have them fail or the adhesive lets go. While in most every case, great products can be sourced from Amazon with enough research. However, this is one of the rare times it doesn’t work out. This is why I am recommending you go with the top quality Bluewater LED boat trailer lighting kit. This kit is IP68 rated waterproof, which is not only submersible, but can be left underwater for the long term.

These kits are available in several colors and are nice and bright. The LED strips have a top grade adhesive by 3M that actually keeps them in place, as long as you properly clean the surface before application. While some people may be thinking of applying under the frame rails, they actually work much better inside the frame rails. These boat trailer lighting kits also come with a waterproof on/off switch that you can install on the trailer if your state requires them to be able to be shut off. It’s a good idea to install the switch anyway.

If you would like to skip using LED strip lighting, but still light up your trailer under water, we have another option. This boat trailer lighting option is from Amazon and is much less expensive. These IP68 rated lights are very dependable, but you won’t have the continuous strip of lights. These are individual pods with 4 LEDs in each. You can pick from 4 colors and they come in sets of 4 or 6 pods and very inexpensive.

If you would like to skip using LED strip lighting, but still light up your trailer under water, we have another option. This boat trailer lighting option is from Amazon and is much less expensive. These IP68 rated lights are very dependable, but you won’t have the continuous strip of lights. These are individual pods with 4 LEDs in each. You can pick from 4 colors and they come in sets of 4 or 6 pods and very inexpensive.

You can buy a couple sets and install them evenly down each side of the inner frame members. When you install them, you can check with your sate and see if they are required to have an on/off switch to be legal. Either way, you are just tapping into your trailer’s existing wiring for the running lights. The only difference would be is whether you run through a switch before the lights. These mount with screws, so you don’t have to worry about the possibility of subpar adhesive.

Boat Trailer Bunks, Guides And Rollers

Most of the time when there is an issue with bunks, they just need to be recovered with carpet. The bunk itself is just treated 2×4 wood lumber for most boat trailers of small boats, though as the boat gets bigger, so does the lumber size. For my Monterey 268ss, the trailer had 4×6 beams on edge for bunks. Either way, replacing the bunk carpet is easy. Below is a video on how to install new carpet onto the inner fenders of a boat trailer and the side boat guides. These boat guides are 2×6 lumber and I wanted a full wrap on them, so I cut material out of a large piece of carpet. However, the process is the same for wrapping the bunks.

If you don’t want to cut carpet out of a large piece, you can select from a couple different sizes of pre-cut bunk carpet that comes in a few different colors on Amazon. The quality is great. Just follow the procedure in the video and you will have professional looking bunks with very little effort. One reminder for you though, is to allow the carpet adhesive to dry for 24 hours before setting your boat on them.

If you don’t want to cut carpet out of a large piece, you can select from a couple different sizes of pre-cut bunk carpet that comes in a few different colors on Amazon. The quality is great. Just follow the procedure in the video and you will have professional looking bunks with very little effort. One reminder for you though, is to allow the carpet adhesive to dry for 24 hours before setting your boat on them.

The bunk carpet is offered in an 11″ x 12′ cut or and 18″ x 18′ cut for larger bunks. You can choose between black, blue, or gray color bunk carpet. It’s made of 100% polyester for quick drying and durability. Remember that when you wrap the bunk, keep the seem on the bottom.

I am a believer that carpet covered bunks are the way to go. Rollers put more concentrated pressure on specific spots on the boat, and they roll easy for the most part. Much like any easy slide material you can buy for bunk covers, the boat doesn’t have much grip on the trailer. Yes, there will be different opinions on this, but when my boat is sitting on my trailer, I want it to stay there. When the boat is being launched or loaded, the trailer is backed into the water as to let the boat float off or on.

I am a believer that carpet covered bunks are the way to go. Rollers put more concentrated pressure on specific spots on the boat, and they roll easy for the most part. Much like any easy slide material you can buy for bunk covers, the boat doesn’t have much grip on the trailer. Yes, there will be different opinions on this, but when my boat is sitting on my trailer, I want it to stay there. When the boat is being launched or loaded, the trailer is backed into the water as to let the boat float off or on.

It’s also true that the boat is being held onto the trailer by the winch and transom straps, but if one of these let go, I don’t want my boat to slide around on the trailer before I can pull off the road safely. If you want to replace your rollers with bunks, there are several kits on Amazon like this one to choose from.

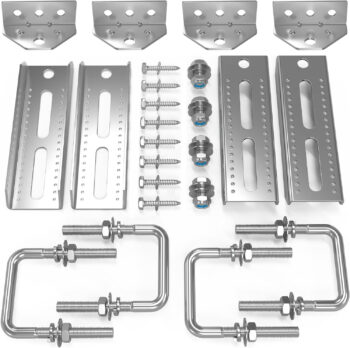

Moving on to boat trailer guides. There are several different styles and sizes of boat trailer guides. I mentioned a set of post style guides above in the boat trailer lighting section. However, since there are so many styles and sizes, I think you should take a look at a bunch of different ones to see what style fits your situation best.

Moving on to boat trailer guides. There are several different styles and sizes of boat trailer guides. I mentioned a set of post style guides above in the boat trailer lighting section. However, since there are so many styles and sizes, I think you should take a look at a bunch of different ones to see what style fits your situation best.

One of the styles of boat trailer guides are like the ones in the video above. These are OK, but I am partial to the post style guides with the post mounted trailer lights on them as I showed above.

- They look cool

- They stick up out of the water when loading

- They provide a place for higher mounted tail lights

- The light on the top of the post provides for easier backing up at night

Speaking of a huge assortment to choose from, lets look at boat trailer rollers for the bow and keel. Some trailers have permanent roller locations, while others have adjustable rollers that can be moved to fit the boat that is on the trailer. Sometimes your boat trailer may not have a keel roller, but you feel it needs one to protect your boat when launching or loading. This CE Smith Galvanized Roller Bracket Assembly just may be the answer. It’s heavy duty and mounts right to your trailer’s cross-member and is fully adjustable.

Speaking of a huge assortment to choose from, lets look at boat trailer rollers for the bow and keel. Some trailers have permanent roller locations, while others have adjustable rollers that can be moved to fit the boat that is on the trailer. Sometimes your boat trailer may not have a keel roller, but you feel it needs one to protect your boat when launching or loading. This CE Smith Galvanized Roller Bracket Assembly just may be the answer. It’s heavy duty and mounts right to your trailer’s cross-member and is fully adjustable.

- Made with hot-dipped galvanized steel for corrosion resistance in marine environments

- Includes roller and 5/8″ shafts for easy installation and use

- Pre-assembled and ready to install

Sometimes your boat trailer came with keel rollers, but they got hard and cracked. In this case, while you are on Amazon, you can just search for a keel roller by size. For the most part, you need to know the over-all width of the roller and you’ll need to know the diameter of the hole that goes through it. You could also measure the diameter of the shaft it goes onto. You are certain to find one.

A bow roller is similar. Just measure your existing one and search it the same way. It would be very strange to not have one at all, because this is part of you bow support post and winch setup. Sometimes you may have a bow stop for your support piece, but I don’t personally care for these. I prefer having a bow roller. I feel it is easier on your boat bow when launching or loading. Also these bow rollers can be very inexpensive (like $4), so don’t be afraid to replace one at the first sign of wear.

Trailer Hitch Couplers

I’m starting to sound like a broken record, but again with hitch couplers, there are many different styles and sizes. These do need to be replaced from time to time, for different reasons. Some get old and rusty. Some have not been maintained or adjusted properly and they wear out. One thing for sure is, that you want to be sure you have a coupler on your trailer that is functioning and properly adjusted. This is what’s connecting your truck to your trailer, that is hauling your awesome boat.

Let’s start small and look at trailer couplers that don’t have surge brakes incorporated into them. Something like a PWC trailer may only have a trailer tongue that is a couple inches wide, but a small boat trailer may have a tongue that is 3 inches wide. In both cases they will most likely attach to a 2″ ball (but not always). Here is the most common style trailer coupler used on these trailers. Here is a Curt 25100 Straight Tongue Trailer Coupler on Amazon that has a 3″ wide channel for the trailer tongue. It also is designed to accept a 2″ trailer ball.

Let’s start small and look at trailer couplers that don’t have surge brakes incorporated into them. Something like a PWC trailer may only have a trailer tongue that is a couple inches wide, but a small boat trailer may have a tongue that is 3 inches wide. In both cases they will most likely attach to a 2″ ball (but not always). Here is the most common style trailer coupler used on these trailers. Here is a Curt 25100 Straight Tongue Trailer Coupler on Amazon that has a 3″ wide channel for the trailer tongue. It also is designed to accept a 2″ trailer ball.

These are designed to be direct bolt-on replacements, but can also be welded in place. Again there are several different size configurations, so if this isn’t the exact size you need, just click on the link and put the sizes into the Amazon search and you’ll absolutely find the right one. This is another boat trailer part that is surprisingly inexpensive and well worth replacing if there is any issues with your current one.

Some boat trailers have an A-Frame design at the tongue that requires a different style coupler. These are generally welded in place. Even with that, they are still pretty straight forward to replace. You just grind off the old weld, then grind the tongue surface flat. Then just weld the new one on. If you don’t have the tools to do this, just buy the coupler off Amazon and take your trailer to a welding shop. It is not a big job and shouldn’t cost much.

The picture to the right is a CURT 25210 Black A-Frame Trailer Coupler. Again, these are very inexpensive and should be changed with signs of wear. Remember that every time you take a turn with your tow vehicle, the ball is rotating and rubbing inside your coupler. Keeping grease inside your coupler prolongs wear, but most people don’t do this, because grease is left on the ball and gets on everything that touches it while the trailer isn’t hooked up.

Here is another style trailer coupler. It is the CURT 25217 Black A-Frame Trailer Coupler. I’m showing this mainly as an option to the one above, but it’s twice the cost and is made for heavier trailers. This style coupler is a more secure coupler, but by the time you would actually need to have something like this, your trailer is much too heavy to go without trailer brakes. This is a 7,000 pound rated coupler, while the other ones above are 5,000 pound rated.

Here is another style trailer coupler. It is the CURT 25217 Black A-Frame Trailer Coupler. I’m showing this mainly as an option to the one above, but it’s twice the cost and is made for heavier trailers. This style coupler is a more secure coupler, but by the time you would actually need to have something like this, your trailer is much too heavy to go without trailer brakes. This is a 7,000 pound rated coupler, while the other ones above are 5,000 pound rated.

When you get into the larger boat trailers, they will have a surge brake system on them with at least one axle having brakes. Most of the time when a surge brake actuating trailer coupler goes bad, it’s because of the actuator side of the system. While you can sometimes replace the guts of one of these boat trailer couplers, it’s going to be easier and sometimes less costly to replace the entire coupler with something like the Dico / Titan Model 60 surge brake actuator from Amazon.

When you get into the larger boat trailers, they will have a surge brake system on them with at least one axle having brakes. Most of the time when a surge brake actuating trailer coupler goes bad, it’s because of the actuator side of the system. While you can sometimes replace the guts of one of these boat trailer couplers, it’s going to be easier and sometimes less costly to replace the entire coupler with something like the Dico / Titan Model 60 surge brake actuator from Amazon.

This is the entry level of where most boat trailers that have brakes will use. It is a very common actuator coupler and is a direct bolt-on replacement. This is an excellent choice.

- Lever Lock coupler fits 1-7/8″, 2″ or 50mm hitch balls

- Bolts to 3″ trailer frame – Zinc plated finish

- 7,000 lb gross trailer weight rating / 700 lb tongue weight rating

In very simple terms, this boat trailer coupler/brake actuator works similar to you stepping on the brake pedal in your car. The difference is that it is the trailer ball that is doing the pressing. When you are hooked up to your boat trailer and you step on the brakes in your tow vehicle, the momentum of the trailer pushing forward against your tow hitch, depresses the bracket actuator in your coupler. There is a brake fluid reservoir in this coupler and as the slide compresses from the forward momentum pressure, it pressurizes the fluid in the lines back to the trailer brakes.

If you need to replace a boat trailer coupler/brake actuator on a much larger boat trailer, this Demco Model DA10 surge brake actuator is ideal for tandem axle and triple axle boat trailers using disc brakes, with a 12,500lb towing capacity. It can handle 1,250 pounds of tongue weight and fits on a 2 5/16 hitch ball. This also has an added feature of an electric lockout solenoid with heavy duty protective shield. In order to properly use this feature, please make sure you have the correct wiring for the electric solenoid; either a 5 Flat or 7 RV plug, which would have the reverse lights from your tow vehicle wired into the plug. Not everyone hooks this feature up, but it’s there.

If you need to replace a boat trailer coupler/brake actuator on a much larger boat trailer, this Demco Model DA10 surge brake actuator is ideal for tandem axle and triple axle boat trailers using disc brakes, with a 12,500lb towing capacity. It can handle 1,250 pounds of tongue weight and fits on a 2 5/16 hitch ball. This also has an added feature of an electric lockout solenoid with heavy duty protective shield. In order to properly use this feature, please make sure you have the correct wiring for the electric solenoid; either a 5 Flat or 7 RV plug, which would have the reverse lights from your tow vehicle wired into the plug. Not everyone hooks this feature up, but it’s there.

If you ever thought about converting your boat trailer brake system over to disc brakes, there is a kit for that! This kit is for a single axle, but most of the time when a dual axle boat trailer has brakes, it is only on the front axle anyway. This is a complete kit with everything you need to install a disc brake, surge brake system. If you decide you want disc brakes on more than one axle, then you just need the caliper system for each additional axle. The DEXTR MARINE Complete Disc Brake Kit uses vented brake discs.

If you ever thought about converting your boat trailer brake system over to disc brakes, there is a kit for that! This kit is for a single axle, but most of the time when a dual axle boat trailer has brakes, it is only on the front axle anyway. This is a complete kit with everything you need to install a disc brake, surge brake system. If you decide you want disc brakes on more than one axle, then you just need the caliper system for each additional axle. The DEXTR MARINE Complete Disc Brake Kit uses vented brake discs.

- Includes a disc brake actuator that features a cast ball clamp

- Oversized aluminum master cylinder pre-assembled with a backflow-style reverse lockout solenoid

- A pair of corrosion-resistant GalvX-coated vented rotor disc

- Using marine-grade aluminum calipers with stainless steel pistons and slider pins

- Complete flexible brake hose kit with brass fittings and all hardware

- 10″ kit fits 13″, 14″ and 15″ wheels

The last item you may be needing in this section would be a receiver hitch. The Rhino USA Adjustable Trailer Hitch is my “go-to”, because it’s very durable, adjustable, and has both 2″ and 2 5/16 balls on it at all times. These are the only two sizes I need for everything I ever tow.

The last item you may be needing in this section would be a receiver hitch. The Rhino USA Adjustable Trailer Hitch is my “go-to”, because it’s very durable, adjustable, and has both 2″ and 2 5/16 balls on it at all times. These are the only two sizes I need for everything I ever tow.

- Whether you need a drop or rise, instantly adapt to any towing situation with the extremely versatile & easy to use ball mount

- 2-Inch hitch ball towing capacity of 8,000lbs + reversible 2-5/16″ ball with a 12,500lb towing capacity for hauling heavy loads

- Comes with both lockable pins

- Engineered from top grade aluminum with oxide block for life-long protection, wear and corrosion

- If you aren’t 100% satisfied for any reason, they’ll refund your money

Boat Trailer Locks

There are lots of different Boat trailer locks available for each component you want to secure. Here are a few ways you might want to lock up your boat trailer:

- Your tow vehicle receiver hitch pin lock

- Lock your hitch ball onto the receiver

- Trailer coupler release lever lock

- A trailer wheel lock

- A ball and cover lock that mounts to your coupler when the trailer in not attached to your tow vehicle

Each one of these locations have several options and would be difficult to cover here. With the right tools along, a thief could get past all of them. The purpose of trying to secure your boat trailer from theft, is to “keep honest people honest”. We want to make it look like it would be too noisy or time consuming for someone who isn’t a professional thief, to steal it.

I personally just use a locking pin on my tow vehicle’s hitch receiver and a coupler release lever locking pin. Am I a target? I guess not, because over 43 years of boating, I’ve never lost one yet (knock on wood, lol).

While you are on Amazon considering the locks I use, you can look over all the options for securing your trailer. Some of these option will depend on whether your boat trailer is hooked up to the tow vehicle or not. Remember that no lock is going to protect against all thieves, but the Proven Industries Model 2516 Trailer Lock is the highest rated trailer lock for when your boat trailer is not attached to your tow vehicle. This particular on that I linked to is only for a 2 5/16 coupler.

While you are on Amazon considering the locks I use, you can look over all the options for securing your trailer. Some of these option will depend on whether your boat trailer is hooked up to the tow vehicle or not. Remember that no lock is going to protect against all thieves, but the Proven Industries Model 2516 Trailer Lock is the highest rated trailer lock for when your boat trailer is not attached to your tow vehicle. This particular on that I linked to is only for a 2 5/16 coupler.

- The locking parts on this device are constructed from hardened steel for increased security, and the exterior cover is tough enough to stop burglars from using power tools, hammers, and crowbars on your lock.

- This trailer lock has a special key design that prevents anyone from picking the lock. This innovative key system also features an interior locking mechanism that stops would-be thieves from making a copy of your key.

If you need one that fits something smaller, use the NenNicht Anti-Theft Trailer Coupler Lock on Amazon. It has similar features and also fits 2″ trailer couplers. It’s also priced at around 1/3 the cost, but if your boat is valuable to you, then the cost of securing it is just “pennies”.

Wheels And Tires

This will be a fairly short section, because there are just too many different wheel and tire combinations that people may want. I will place a couple links in this section that are specific search results, so you can just start looking at options without having to work through finding the correct search terms that get the best results. Generally speaking, people don’t really consider what they would like for wheels and tires on their boat trailer, until the tires get old or worn.

The first thing to go bad is, usually the tires start getting cracks on the sidewalls. This is because most boats are used locally and the trailer doesn’t get many miles to wear out the tread. Instead, the tires get old and weather checked. A lot of new boaters check the trailer tire’s condition, by looking at how much tread is left. The first thing they should actually look at is the sidewalls, for cracking.

With that said, if you plan on keeping the same rims, be sure you are replacing the tires with actual trailer tires. Don’t use car tires. Now I’m going to give you an example of what it’s like to buy just tires, versus tires and rims fully mounted and ready to go. If you were to buy two ST175/80D13 trailer tires only from Amazon, it would cost about $85 for both. Then you would have to drive to a tire shop and pay them to remove the two old tires and to mount the two new tires. So all in, your cost would be around $130. plus your time and fuel, to and from the tire shop. Call it $150.

With that said, if you plan on keeping the same rims, be sure you are replacing the tires with actual trailer tires. Don’t use car tires. Now I’m going to give you an example of what it’s like to buy just tires, versus tires and rims fully mounted and ready to go. If you were to buy two ST175/80D13 trailer tires only from Amazon, it would cost about $85 for both. Then you would have to drive to a tire shop and pay them to remove the two old tires and to mount the two new tires. So all in, your cost would be around $130. plus your time and fuel, to and from the tire shop. Call it $150.

Now if you go on Amazon and order theseST175/80D13 trailer tires already mounted on brand new black rims, They would show up at your door ready for you to put on your trailer for $166. You wouldn’t have to drive anywhere. You wouldn’t have to clean the old rims. You would have a brand new set for an extra $16 over buying just the tires alone. This is a “no-brainer” if you want to stick with standard steel rims (which is totally good for a lot of people). To find the size you are looking for, just go to the link and then type in your trailer tire size in the search box.

Now if you go on Amazon and order theseST175/80D13 trailer tires already mounted on brand new black rims, They would show up at your door ready for you to put on your trailer for $166. You wouldn’t have to drive anywhere. You wouldn’t have to clean the old rims. You would have a brand new set for an extra $16 over buying just the tires alone. This is a “no-brainer” if you want to stick with standard steel rims (which is totally good for a lot of people). To find the size you are looking for, just go to the link and then type in your trailer tire size in the search box.

If you’re thinking it might be nice to have custom aluminum rims to go with your new trailer tires, you would likely want to buy the rims and tires seperately. There is a large selection of really cool custom rims for trailers, so this is where I’m going to provide a search link for you to find a custom aluminum rim for your boat trailer on Amazon. Normally, boat trailer rims are simple to size, and usually have a zero offset. However, if the custom boat trailer rim you like requires more measurements, the video below provides a very easy to understand way to measure what you need.

If you’re thinking it might be nice to have custom aluminum rims to go with your new trailer tires, you would likely want to buy the rims and tires seperately. There is a large selection of really cool custom rims for trailers, so this is where I’m going to provide a search link for you to find a custom aluminum rim for your boat trailer on Amazon. Normally, boat trailer rims are simple to size, and usually have a zero offset. However, if the custom boat trailer rim you like requires more measurements, the video below provides a very easy to understand way to measure what you need.

The last item you should consider is wheel locks. While someone stealing your boat trailer wheel might be a rare occasion, why not just add on keyed wheel locks? They are very inexpensive, and easy to install. Do you really want to risk some unscroupuless person who needs a spare, taking one of your wheels? If you made the decision to put new wheel and tires on, then just add on a set of wheel locks so you get to keep them. I would suggest using McGard wheel locks. Click on the link and if you happen to need a different thread size, just click on the McGard name, just above thier star rating. There you can put your thread size into the search bar and get exactly what you need.

The last item you should consider is wheel locks. While someone stealing your boat trailer wheel might be a rare occasion, why not just add on keyed wheel locks? They are very inexpensive, and easy to install. Do you really want to risk some unscroupuless person who needs a spare, taking one of your wheels? If you made the decision to put new wheel and tires on, then just add on a set of wheel locks so you get to keep them. I would suggest using McGard wheel locks. Click on the link and if you happen to need a different thread size, just click on the McGard name, just above thier star rating. There you can put your thread size into the search bar and get exactly what you need.

I added wheel locks for your boat trailer wheels, because I was in the northwoods of Wisconsin a few years back, and when I was bringing my boat to the public boat ramp, there was a guy there that seemed very upset. As I was walking up to get my truck and trailer, I asked him what was going on. He said that someone stole his trailer wheel! I walked with him to his trailer and there was a log under the axle and the wheel was missing.

His wife and kids were upset as well. I looked at his wheel and tire size and it happened to be the same as mine. I took the lock off my spare and gave it to him. The family was very relieved. I gave him the address of the lakehouse I was at, and later that night, he showed up with my spare. He had went and bought a replacement and returned mine. Mine is a custom rim to match my trailer.

This was a stand-up guy who was very appreciative and we all had a cookout around the campfire. The person who took advantage of him on the other hand, will probably receive his karma at some point in life.

Boat Trailer Fenders

Boat trailer fenders get broken and bent all the time. The most common way they get beat up is from backing into things. Some fenders are not meant to be stepped on, but people do it anyway and break the fender. Plastic fenders often have a molded in location for a step, but that doesn’t mean just anyone should step there. They can only handle so much weight. This is also true for some dual axle setups. While most are made of steel or aluminum, certain points on that fender can not handle an enornous amount of weight.

Boat trailer fenders get broken and bent all the time. The most common way they get beat up is from backing into things. Some fenders are not meant to be stepped on, but people do it anyway and break the fender. Plastic fenders often have a molded in location for a step, but that doesn’t mean just anyone should step there. They can only handle so much weight. This is also true for some dual axle setups. While most are made of steel or aluminum, certain points on that fender can not handle an enornous amount of weight.

Just know that you likely will be replacing some boat trailer fenders, fender mounts, fender step traction pads, fender edge trim molding, etc. From personal watercraft trailers up to large boat trailers, you will find great replacement parts for boat trailer fenders, parts and accessories on Amazon at the lowest cost and fastest shipping.

Sizing is very typical for boat trailer fenders. So if you have a PWC trailer and you want replacement fenders for it, you’ll find that the shape of the fender is pretty much a dead giveaway to finding the replacement. When you’re on Amazon, look down the search I provided above and when you see the same shape as yours, just open that ad and read the description. It’s almost certain you’ll have a match.

If you are looking to replace the fenders and the mounting brackets, there are some great trailer fender step mounts that serve a dual purpose. With the trailer sitting on the ground, set a spacer on top of the tire(‘s) that provide the clearance you want between the fender and tire(‘s). Set the fender on top of the spacers and locatte the fender forward or backward to get a centered location. Then clamp your new fender step mounts in place and drill your mounting holes. It helps to have a helper during this, but one handy person can do the job. If its dual axle, don’t forget your center supports for between the wheels.

To aid in standing along the trailer frame to access the inside of the boat, you’ll find these trailer steps to be incredibly useful. They’re all 6″ deep, and you can get them 9″ long, 20″ long, or 30″ long. This will give you the variety you need to have a step anywhere around the boat trailer that you need.

Bow Support Posts and more

Your boat trailer most likely has a bow support post on it already and the fact is, not much can go wrong with them other than it’s wear items like rollers and winches. The boaw support post has a couple important jobs. One of which is holding your boat onto the trailer, but the most important one is making the boat a part of the trailer’s structure.

Have you ever watched an empty boat trailer going down the road and seeing it flex and twist a bit? Some boat trailers are built very heavy duty, but most actually flex some. Once the boat is on the trailer and winched tight at the bow, and also held down tight by the transom straps, the whole thing becomes one. An empty trailer is a set of square tubes welded together to form a relatively flat structure. So for a minute think of it like a flat piece of cardboard. It is similar because cardboard is corrigated, so there is a tube like strucure to it. The cardboar on it’s own can flex.

Now image attaching a block of wood to it. It no longer can flex. When your boat is properly held down onto your trailer, it does the same thing. It becomes one ridged structure. Keep in mind that this only works if the boat is continueously held down tight. If any strap gets loose, you lose that ridged structure. This is when your boat is allowed to move seperately from the traile when going over bumps. Not ony do your winch and transom straps need to be high quality, but so does your bow support post.

This is why I want to show you what NOT to buy first! Look at the picture to the right and you will see the post itself is not bad. However, the bow support roller bracket is unacceptable in my opinion. This style is a cheap design that is used for smaller boats, BUT it is not good for them either. As your trailer goes down the road with a boat strapped to it, there is not only downward pressure applied to the bow roller. There is also upward pressure applied when your hitting bumps in the road.

This is why I want to show you what NOT to buy first! Look at the picture to the right and you will see the post itself is not bad. However, the bow support roller bracket is unacceptable in my opinion. This style is a cheap design that is used for smaller boats, BUT it is not good for them either. As your trailer goes down the road with a boat strapped to it, there is not only downward pressure applied to the bow roller. There is also upward pressure applied when your hitting bumps in the road.

That is just a pinch bracket squeezing on the bow support post. Because of the angles in the design, it will have a better (not good, but better) chance of holding up to downward pressure. However, there is little chance of it holding up to upward pressure caused by bouncing off bumps in the road. I would not suggest using this kind of bow support post design, even for your smaller boats that you care about. Welded, U-bolt, or solid bolt-through configurations are the way to go. Welded is best, but they have to be adjustable in some aspects to fit to your boat.

To the right are a few boat trailer bow support posts that are on Amazon, so you can see the designs that are more safe for your boat. Winches and bow rollers were touched on earlier in this article, but I do want to mention another thing to consider regarding locking your boat down to the trailer, before we end.

To the right are a few boat trailer bow support posts that are on Amazon, so you can see the designs that are more safe for your boat. Winches and bow rollers were touched on earlier in this article, but I do want to mention another thing to consider regarding locking your boat down to the trailer, before we end.

I see a lot of people attaching the winch to the boat incorrectly, so I just want to explain why you should consider doing it my way. This will also tell you how you need to setup and adjust your boat trailer bow support post and bow roller.

First off, with the boat sitting in the correct position on the trailer, move your bow support post (if necessary) close enough so you are ready to adjust the bow roller. Just snug down a bit on the post mount bolts. You want the center of the bow roller to be just above the center of your boat’s bow eye-loop. Once in position, tighten all the bolts down.

From the winch, pull the winch strap through the gap, just under the bow roller and hook it to the bow eye-loop. Draw the winch up tight. The reason for routing your winch strap this way, is to stop the boat from having the ability to move up or down. Because the winch strap is run under the bow roller, it would have to break the bow roller in order for the boat the lift up. Clearly it can’t move down any further, because it is winched downward against the bow roller and putting pressure on the bunks. By pulling down on the transom with the transom straps ads pressure down on the bunks, as well as a little more pressure up on the winch strap, which is already stopped by the bow roller.

This again, makes the boat trailer and the boat into one unit. Thanks for taking the time to read about the various boat trailer accessories that can make boating life much more pleasurable. Please remember to check if you need to have license plates on your boat trailer before hitting the road.

Repack your bearings with

Repack your bearings with